Building your own catamaran is another option to getting into your own boat.

In this page we will go over the advantages, considerations, and a detailed

history and journal of our boat-building adventure with Light Wave.

We hope this will give you a clear picture of what lies ahead if you go this

route, including:

- Construction methods

- 9 essential design features

- Review of the four leading catamaran

designers for home builders - Construction times

- Budget: How much did it cost

to build a basic cruising catamaran? - Layout of our catamaran, LightWave,

and lots of pictures - Carllie’s article from September 2000 Multihulls Magazine:

“The Boat Builder’s Wife“ - Equipment outfitting

- Radio and communication outfitting

- Dinghy selection and considerations

- Having a boat custom-built for you

Because of the huge dollars needed to buy a new or even a used catamaran, we

would never have gotten a catamaran if we hadn’t built it ourselves.

Let’s start by saying that building any type of larger boat, especially a

catamaran, can be one of the most intellectually and physically challenging

things you will ever do.

It has

been said that building a large boat is the closest a man can come to giving

birth to a baby. In other words there is going to some discomfort and pain along

the way; you will question yourself on whether this was such a good idea; it’s

very difficult to reverse the decision; and though friends will support you,

you will be on your own most of the time with your significant other if he/she

is game.

There are several big pluses to building your own boat.

Know your boat

You will intimately know every part of your boat. You will know where every

wire, hose, bolt, bulkhead, rib, and support is because you installed them!

Pride of ownership

We have often thought what it would be like to just buy a boat from a manufacturer,

and know that while owners who have spent a lot of cash (or future life to pay

off the lien) their often possessive and competing-with-the Joneses could not

begin to compare to our quiet glow of happiness and akinship we feel with Light

Wave.

Our boat is like part of the family. So much time was spent on her that we

have a major emotional investment. Every time we see our vessel – from a distance

at anchor or approaching her in our marina, we say, “What a pretty boat!

I can’t believe we built it!” Then that sense of accomplishment settles

back in and we feel we have indeed earned the privilege of all of the beautiful

experiences we have had sailing, cruising, exploring the beautiful BC Coast

and much further a field (or should we say “an ocean”?).

Save money

You will be able to pay for the materials as you go and “donate”

your time to the cause.

Get a newer design

Many of the production boats that are out there are designs of many years

ago because the manufactures have to recoup their capital investment on the

mold and production setup. When you build your own you have much newer designs

to draw from.

Details on Our Boat Building Adventure

Where

Where

do we start? First of all, Carllie has her own version of events and the process

and her story, called the in “The

Boat Builder’s Wife“, appeared in Multihulls Magazine in Oct 2000.

So here is my version of it:

We had sailed our first boat Wave Dancer for five

years and had many adventures on the British Columbia coast. In May 1996, I

had just returned from a little one-week solo trip in the Gulf Islands of BC

when I bought the book, The Cruising Multihull by

Chris White (Future link to book review on our web site).

This is the book that got me going (Carllie was not yet convinced). I must

have read it a half dozen times over the next 6 months, each time becoming more

convinced that this was the way to go for our next boat. It was really still

pre-internet web site days so I wrote to all the designers that were listed

in the back of the book. Over the next several weeks packages of information

started appearing in the mailbox (there is just something about getting packages

in the mail – I guess it’s the anticipation). I would pour over these

preliminary printed pages with pictures and accommodation layouts. Next, I put

a few dollars down to buy the information packages and study plans from the

top prospects.

I should

I should

digress to explain that we had never sailed a cruising catamaran. Our only experience

with multihulls consisted of some summer sailing on a 12-foot AquaCat beach

cat, definitely first generation. It went about 6 knots and that was it. My

only other experience was when I was in my early teens back in Montreal: my

father had bought this little bathtub-like trimaran about 10 feet long. I don’t

remember the make. It didn’t go very fast. The most fun we had with it

was trying to get the bows to plow under while sailing so the cockpit would

fill with water (I must see if I can get a picture of it out of the family archives…..).

I waited patiently for the study plans. It was like the night before Christmas

when I was kid. Oooh the wait! Finally they came, and again I carefully scrutinized

the next level of detail. Things were getting a little more serious. The top

contenders were:

- Richard Woods

- Chris White

- James Wharram

Click here to read my comments and reviews

on their catamaran designs as well as

those of Jeff Schionning.

I remember initially drooling over the Atlantic 42 by Chris White, still one

of my favorite designs. It seemed to be so seaworthy (by the way if I run into

about $800,000 USD any time soon, I am going to buy an Atlantic 55). The most

important piece of advice that came out of the material was from Richard Woods:

“Build the smallest boat you‘d

be happy with it.”

What

What

does that mean? Each page in these plan books covers one design. Though there

are differences in the accommodation plans, they are all scaled to fit a single

page. You look at this 35 footer and you go “Wow! Doesn’t this look

nice?” The little 30 footer doesn’t seem to be as good and so forth.

Since they are each one page the one thing that doesn’t really come across

is how much more work is that 35 footer over the 30 footer! This brings me to

Garett’s #1 axiom of catamaran boat building:

Axiom #1: The hours to build a catamaran is

in almost in direct proportion to its weight.

Which brings us to Axiom #2:

Axiom #2: It takes about 1 hour to create

1 pound of finished boat.

In our case we spent 3,500 hours (click

here for full details on the construction hours) to build a 4,000 lb. boat

(just a little less than 0.9 hours per pound). If a boat’s empty weight

is 8,000 lbs., it will probably take about 6,000 hours to build.

When you think about it, you can only mix and handle so much material per

hour. More boat weight, more material, more hours. Sure there are some economies

of scale on a bigger boat, but usually the systems become more complex and these

take longer to install.

Anyway, back to the decision process: Richard Woods out of England included

a video in his design package. I guess this is what sold Carllie and I on his

designs. Using Richard’s axiom of “Build the smallest boat you’d

be happiest with,” we compared his 30 foot Sagitta with his 28.5 foot

Gypsy. In the end the fact that Gypsy could be built in components swayed us

to pick that one. Many of the initial parts and components could be built in

a garage.

This decision process took 8 months and I figured we’d launch in 6 months.

It was now January of 1997. Little did we know it would be 26 months and 3,500

hours between the two of us until we launched on June 5, 1999. We ordered the

full plans and we were off and running.

We were ready to build, but where would we start the process? First of all,

we live in a tiny 480 sq. ft. apartment in Vancouver. Back-yard building wasn’t

exactly an option so I found a small garage nearby that we rented for 5 months.

I had

I had

some wood delivered and lots of epoxy and on Sunday, February 23, 1997, the

day before my 40th birthday, I cut and glued the first pieces of wood which

would eventually make up the mast beam. Over the first few months, it didn’t

really seem like I was building a boat. Most of the stuff at the beginning were

small things. It was like I was building a model.

After about 4 months in the garage, I had made all the small parts and it

was time to build the hulls. This meant that we had to go larger facilities.

We found space at Shelter Island Marina and Boatyard in Richmond. This is the

biggest boat yard in the Vancouver area with dozens of commercial and private

projects, big and small, under way.

I went

I went

out and bought one of these big hoop greenhouse buildings. Since the boat was

29′ by 18′, I thought that a building 36′ by 24′ would give enough room around

the boat. I took a week off work to erect our shed. I had a couple friends help

me for a day and then we covered it with some heavy plastic. When the building

was completed and we walked inside it really hit me, “Wow! this is big!

It’s like a covered football stadium! We are going to build a boat that

is going to fill this?” By the way we discovered it’s better to use white

opaque tarps rather than the clear plastic we used – which definitely creates

a greenhouse effect in summer!

We were out of money by then, so we sold our first boat so we could buy resin

and fiberglass. It was a traumatic time as we said goodbye to our beloved Wave

Dancer. We were now committed. We than had all the foam for the

hull cores, barrels of resin, and huge rolls of matting and roving needed for

the fiberglass skins delivered to our “domed stadium”. We kicked

ourselves many times that we didn’t take a picture of this raw material stacked

in one corner of the empty shed, so we could later show “before” and

“after” photos. It was time to build the hulls.

Up to that

Up to that

time I had done most of the work in the garage on my own. It was at this time,

July 1997, that Carllie and I really started to work as a team as we learned

to laminate the hull sides on our big flat mold. We worked every night after

work and every weekend. Over the next 6 weeks we made all the hull panels and

bonded them all together over the bulkheads. We had friends come out to help

turn the hulls. By the end of August, we had two open hulls sitting in our boat

shed.

Over the next several months we proceed to join the hulls with the beams I

had built in the garage, and then to install the cuddy cabin, cockpit, and decks.

By the spring of 1998, it was staring to look like a catamaran. Through the

spring and summer of 1998, we continued with the major structural components:

mini-keels, hatches, stairs, and interior. Then we went on to the very laborious

work of fairing the boat before painting. Don’t under estimate that job!

All

All

through our boat building, Carllie kept reminding me (nagging?) that she didn’t

want our boat to look “homemade”. With that motivation, I kept fairing

and sanding and fairing and sanding…..

By October 1998 we were ready to prime the boat and start painting. I really

thought this would go quickly. I forgot that I would have to do two

more complete sandings to sand off and finish the two layers of primer

application. In addition we had to fill countless pinholes – a laborious process

somewhat like hiking up a mountain – each time you get to what you think is

the top, you see another summit!

The boat seemed to get bigger and bigger. Believe me, there is a lot of surface

area on a catamaran. I clearly remember that last sanding: I had reached the

end of my physical and mental endurance – I was exhausted. I was ready to move

on to the next phase – any phase but more sanding!

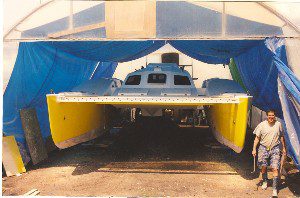

We now started spray-painting the hulls bright yellow. It was around this time

we decided on our boat name of Light Wave. The painting

took over a month: the hulls being the easy part, it was the topsides, the nonskid,

and all the masking and prep that seemed to take forever. Happily, the worst

of the dust was gone.

By March 1999 we were in the home stretch. The center bridge deck cabin was

completed so we took a week off from our paid jobs and lived on the boat in

the shed so we could work all day and not waste time commuting. March, April

and May were frantic months as we finished all the final touches: engine installation,

rudders, windows, deck fittings, electrical, plumbing, mast, and rigging. See

our outfitting page (for more details on what we picked and why, and things

we would do differently now.

Initially, our electronic systems were relatively basic but included GPS and

autopilot see the following link for all our electronic

outfitting choices and reasoning for more details.

It was May 22, 1999 and we decided that Saturday, June 5th would be “Launch

Day” so we could send invitations to all of our friends. On the Friday

night before Launch Day, we still had a number of final things to do, many of

them outside. Unfortunately it was pouring rain. We were tired and very wet

but the boat had to go into the water next day so we persevered on till everything

was ready.

Launch Day finally arrived! We have been to several boat launches over the last

10 years and they are very special times. Just recently we were even at one

where there was a full marching! We didn’t have a band but we did have many

friends! It became a truly grand day as the skies cleared with a blustery wind

and 40 friends joining in the festivities. A couple of short speeches and then

we were ready to launch.

The moment of truth came as Light

Wave was lowered into the water. While still in the slings

of the Travelift, I jumped aboard to check for leaks. Of course there weren’t

any! More food and laughs and tours of the boat for all attending. It was a

great day.

Emotionally drained that night, we slept in Light Wave

in the water for the first time. It was another week before we actually went

out for our first trip as we had to sell the shed, setup sails, and install

some final deck hardware.

There is

There is

more to write tell, about so check back over the next few weeks as I add to

this page.

To sum it up, building a catamaran was a great experience. We learned a lot.

Carllie and I grew closer together through it all. We had a great time doing

it. We had a beautiful catamaran to show for it. Now it was time

for a catamaran adventure!